Distributors of moisture meter products and accessories often need to carry a wide variety of tools and accessories to meet the moisture testing needs of their clients. However, one key tool that many distributors need to carry isn’t technically a moisture meter—it’s a thermo-hygrometer.

These moisture testing tools don’t measure the moisture content of building materials, plants, or other materials directly. Instead, thermo-hygrometers measure the amount of moisture in the air compared to how much moisture would be required to achieve saturation based on the ambient temperature—a.k.a. the relative humidity (RH) of the air. Because of this, these devices are also known as relative humidity sensors, or RH meters.

The question is, why should moisture meter distributors carry thermo-hygrometers for their customers?

A few reasons include:

Because Thermo-Hygrometers Are Needed for ASTM F-2170 Testing

For moisture meter distributors working with flooring installers, construction workers, and anyone else who has to test the moisture conditions deep within a concrete slab for any reason, RH meters are a must-have item.

This is because thermo-hygrometers with in-situ probes are a key requirement for the ASTM F-2170 concrete testing standard. Without a relative humidity sensor deep in the concrete slab, the alternative is to do surface-level testing with a moisture meter or chloride solution—which only reveals moisture close to the surface of the concrete slab and not deep within it.

To Prevent Flooring Issues

Missing excess moisture in concrete floors can mean missing deep pockets of moisture in a slab, which might cause problems later on when that moisture passes from the concrete and into whatever flooring system is installed above it.

When moisture from a concrete slab is transferred into wooden flooring, for example, the wood may start to swell—causing different pieces of wood to push against each other. This can cause warping and/or cupping in wood floors.

For tile, excess moisture can compromise the adhesive used to connect the tile to the subfloor, causing loose or uneven tiles.

By using thermo-hygrometers and following the ASTM F-2170 testing standard, a distributor’s flooring customers are better able to determine whether there is a significant risk of excess moisture being released into their flooring systems. This allows them to take the appropriate measures to prevent such problems.

Because RH Meters Can Help Restoration Efforts

If a distributor of moisture meters has customers who specialize in the restoration of buildings following a disastrous event, such as flooding or fire damage, relative humidity plays a key role in their work. For these customers, carrying thermo-hygrometers and their accessories should be a given if the distributor is already selling moisture meters.

Relative humidity sensors can help restoration professionals track the overall progress of their dry out/tear out efforts to remediate excess moisture in a structure. By using thermo-hygrometers to track the ambient humidity in different parts of the structure, restoration experts can determine how much of an impact their dry out efforts are making.

If the ambient humidity remains high in one room compared to others, it is likely that there is a moisture intrusion source somewhere in that room. Knowing this helps restoration experts focus their search for sources of moisture where they’re most needed—saving time, effort, and money.

To Help Control Lumber Production

For moisture meter distributors with customers in the wood & lumber manufacturing industry, moisture meters can be an invaluable tool for determining if their wood is at equilibrium moisture content (EMC). But, how do they know what the EMC level is in the first place?

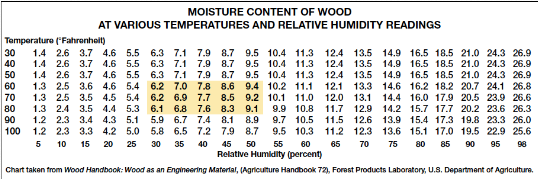

The fastest way to check the EMC is to first find the relative humidity of the area where the wood is being stored and consult the following chart:

Thermo-hygrometers can help establish what the relative humidity and temperature conditions are for the lumber storage area so lumber and wood product manufacturers can determine the appropriate EMC for their wood. This is typically faster and more reliable than simply repeating moisture content tests every six to eight hours until the wood’s %MC stops changing.

Using an RH meter can also be valuable for adjusting climate controls in a lumber storage area. This is common for wood and lumber manufacturers who ship their products to other states where average RH and temperature conditions might be different from their production facility. Here, the relative humidity sensor is useful for making sure that the storage area’s climate has been suitably adjusted to match the ambient humidity conditions at their product’s destination.

By doing this, wood and lumber manufacturers can help to avoid some quality control issues related to the wood's EMC levels being off when it arrives at its destination—such as warping, cracking, or buckling.

Because it Helps Make Distributors a One-Stop Shop

One of the biggest reasons to carry thermo-hygrometers for your customers is that it can help you be a true “one-stop shop” for your customers who need to monitor moisture conditions. And, when your customers need a way to check relative humidity conditions, you want them to rely on you to have the solution that they need. By carrying thermo-hygrometers, you can fulfill that need. If you need help determining what moisture meter solutions would be the best for your customers, contact the experts at Delmhorst Instrument Co. We’ll be happy to discuss your customers’ moisture and relative humidity testing needs!

Comments