How to Use the TotalCheck Moisture Meter to Save Time and Money

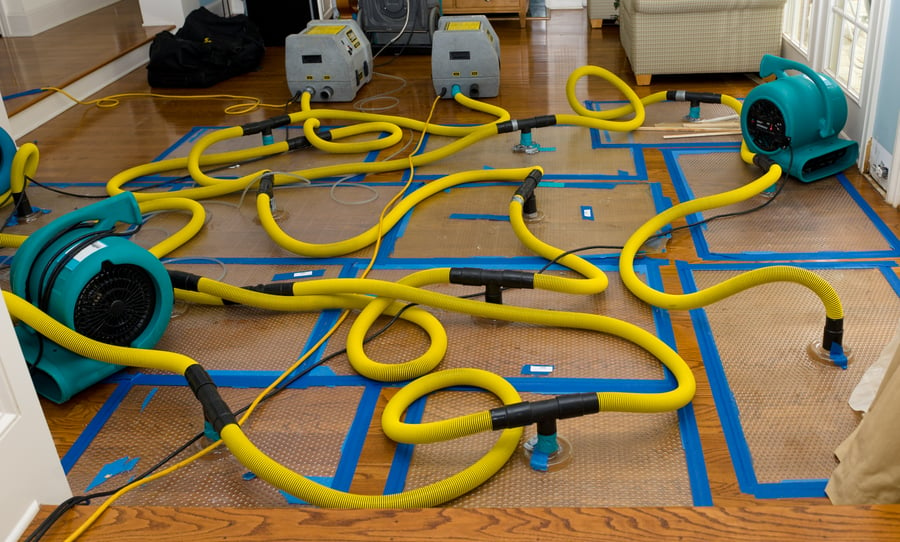

For many moisture meter users, time is of the essence. Restoration professionals need to know where hidden moisture lies in a structure as soon as possible to minimize or prevent water damage. Lumber manufacturers need to know if all of the wood they’re processing is ready for distribution. Real estate agents might not have a wealth of spare time to test for moisture in a structure.

For many moisture meter users, time is of the essence. Restoration professionals need to know where hidden moisture lies in a structure as soon as possible to minimize or prevent water damage. Lumber manufacturers need to know if all of the wood they’re processing is ready for distribution. Real estate agents might not have a wealth of spare time to test for moisture in a structure.

However, just as speed is important for moisture testing, so, too, is accuracy. Many restoration experts need to know precisely where moisture contamination starts and ends. Lumber manufacturers need to know moisture content for both the shell and the core of their wood boards.

So, how can you save time and money on your moisture testing while ensuring moisture meter accuracy? One trick is to use 2-in1 or 3-in-1 moisture testing tools such as the TotalCheck moisture meter to speed up the moisture testing process and get accurate moisture measurements.

Scanning Large Areas Quickly with the Pinless Moisture Meter Mode

Pinless moisture meters have a significant advantage over pin-type meters when it comes to being able to check large sections of a structure quickly. As long as the scanning plate on the bottom of a pinless moisture meter can make solid contact with the surface being scanned, it can get a reliable measurement of moisture content.

Many restoration experts and real estate professionals use pinless moisture meters so they can minimize the time they spend testing different building materials. Lumber manufacturers can use pinless moisture meters to check large numbers of flat wood boards as well.

Even when using a reference scale moisture meter, this provides a swift pass/fail check for moisture content. Because the TotalCheck 3-in-1 meter uses a reference scale for its pinless meter mode, it is often used to quickly establish whether or not building materials are compromised.

Users simply need to test a dry sample of whatever material they’re going to check first, so they can know if the reference scale reading is high or low for that material. Once that’s done, they can just push the scanning plate against the material being tested, take a quick reading, lift it, and repeat until they’ve covered everything they needed to check. This takes a fraction of the time that using a pin moisture meter to check the same area would.

Getting Detailed Information with the Pin Moisture Meter Mode

While the reference scale mode of the TotalCheck’s built-in pinless meter can get fast pass/fail assessments of moisture in different materials, it cannot provide a quantitative measurement of moisture content. To get that quantitative data, users need to use a moisture meter that is calibrated for the specific type of material being tested.

The TotalCheck 3-in-1 meter’s pin moisture meter mode has both drywall and wood moisture testing scales to provide accurate, quantifiable moisture measurements in both of these materials—making it invaluable for restoration, real estate, and lumber manufacturing applications.

After getting an idea of where all of the moisture pockets are in a structure, or a stack of lumber, the pins on the TotalCheck can be inserted into the moisture-compromised area to get a precise reading of moisture content. If insulated contact pins are used, users can easily identify the exact depth of a moisture pocket in a structure, or establish shell and core moisture content in a lumber board.

Additionally, the pin moisture meter mode can be used to test moisture in materials with an uneven surface that a pinless moisture meter couldn’t check. With extended-length moisture probes, the TotalCheck can even be used to test for moisture in insulation with ease. Moisture meter accuracy is ensured by calibrating the device to verifiable NIST standards and can be tested using a moisture content standard (MCS).

Checking Humidity Conditions with the Thermo-Hygrometer

As noted earlier, the TotalCheck is a 3-in-1 moisture testing device—it combines a pin moisture meter, a pinless moisture meter, and a thermo-hygrometer all into one convenient tool. The thermo-hygrometer is valuable to restoration, real estate, and lumber manufacturing pros for a couple of different reasons.

-

Quickly Identifying Moisture-Compromised Rooms in a Structure. Real estate and restoration experts can use the thermo-hygrometer mode to test the ambient relative humidity conditions in a structure room by room. Abnormally high relative humidity (RH) levels in one area can be a strong indication of moisture intrusion—helping restoration and real estate pros focus their search on the rooms that are most likely to be compromised.

-

Verifying Wood Acclimation Conditions. Relative humidity is a big deal for lumber manufacturers—especially in the spaces where they store and acclimate their lumber for future distribution. By checking the relative humidity of their storage areas, lumber manufacturers can make sure RH conditions therein match those of the area the wood will be shipped to—which helps to prevent issues later on after the wood has been shipped out. This helps to save time and money on dealing with customer complaints about wood cracking or swelling.

Need help finding a moisture meter distributor who carries the TotalCheck 3-in-1 meter (or other moisture testing tools)? Check out our Dealer Locator today!

Subscribe to Our Blog

Post Related

How Moisture Meter Technology Benefits the Water Damage Restoration Industry