How to Check Lumber Acclimation with Moisture Meters

If you’re in the process of a hardwood floor installation or a simple wood trim and casework, then you’re likely already aware of the importance of letting the wood product get adjusted to the environment before you begin anything. You see, wood is a complex, hygroscopic material that doesn’t remain the same in shape depending on what type of environment it’s located in.

What’s the reason? Humidity. In warmer, more humid climates, the wood structure absorbs moisture, causing it to expand while drier air makes it contract.

When handling a major project such as a wood floor installation, it’s recommended that you allow the wood to expand or contract prior to putting it in place. This process is also known as acclimation.

This way, when the wood starts to expand, it will do so before installation so that the individual planks won't push up against one another. Also, when the wood begins to contract, the installation will have already taken that into account and gaps will not show during the colder, less humid times of the season.

The Importance of Acclimation

Fortunately, for installers and woodworking professionals alike, the use of a wood moisture meter can help determine when the wood is properly acclimated to its new environment. Acclimation isn’t just about letting the wood lay around to get used to the environment like a newly adopted pet in your home. It’s a bit more complicated than that.

The NWFA recommends that wood floor be acclimated for at least 5 days inside a well climate-controlled environment. Why make sure that the HVAC is on? Because maintaining the temperature and relative humidity that the building will normally be at will allow for better acclimation of the wood.

The NWFA recommends that wood floor be acclimated for at least 5 days inside a well climate-controlled environment. Why make sure that the HVAC is on? Because maintaining the temperature and relative humidity that the building will normally be at will allow for better acclimation of the wood.

It’s important to keep in mind that thicker, more dense samples of wood will likely take longer to acclimate.

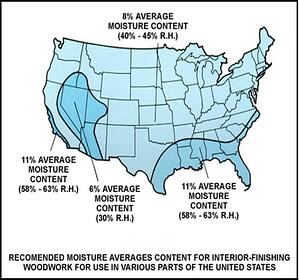

Much of measuring the proper moisture content in your wood has to do with the region in which you’re doing the installation. Areas in the deep south are notorious for their high humidity. With that said, areas the west with dry, desert climates will need different tactics to ensure a reliable and durable project.

How Moisture Meters Can Help

Constant checking of the wood’s moisture content (%MC) is beneficial to see how far along the wood is in the acclimation process. You should check the %MC in a few checkpoints:

-

right before the wood is shipped;

-

when it arrives to the job site;

-

multiple times during the (at least) 5-day acclimation period;

-

prior to installation; and

-

right after installation

Using a moisture meter that doesn’t have pins, is often recommended after installation because pin holes may show after the project’s completion. The combination of the consistent controlled environment and your constant moisture checking should give you a good gauge as to how prepared your wood is to be installed. Take it a step further to ensure a sound installation by checking the subfloor as well.

Ideally, if you can manage to control what season you’ll be performing the installation, winter is the best time of year to make it happen. Consequently, that means summer is the worst as the environment will be more humid and you’ll have expanded wood that will likely make installations difficult.

To find out which moisture meters will benefit your next wood installation project, feel free to browse our collection of flooring moisture meters or woodworking meters. For more information on the best acclimation techniques or how to better install your next wood project, feel free to contact one of our representatives today!

Subscribe to Our Blog

Post Related

Moisture Content

Moisture Meter

moisture meters

pinless moisture meters

Delmhorst

lumber industry

lumber

Moisture content in lumber

moisture levels

pin-type moisture meters

woodworking

Your Guide to Choosing the Best Moisture Meter for Your Woodworking and Lumber Applications