How Does the Relative Humidity Affect the Quality of Wood?

For many woodworking professionals, the complications that the relative humidity (RH) of their work areas can cause is a constant concern. Many manufacturers check the moisture content percentage of their wood religiously, but still come across problems because they forgot to take the RH into account.

What is relative humidity? And, how does it affect the quality of wood?

Defining Relative Humidity

Relative humidity is the term used for the measurement of how much moisture is in the air relative to how much moisture the air will hold before it begins condensing into water. Relative humidity differs from actual humidity because it is a relative value of the amount of moisture that would be needed to saturate the air at the current temperature, whereas absolute humidity is a measure of the air’s actual moisture content.

RH for a given area may change depending on the ambient temperature and the absolute humidity. The colder the air in a given area is, the higher its RH value will be. Warmer areas will have a lower RH value because it takes more moisture to reach the saturation point where it will condense into water.

How RH Affects Wood Quality

Wood is a material that continually absorbs or releases moisture until it reaches a balance with its surroundings. Or, as the experts might say, it’s a hygroscopic material.

So, if you were to leave a piece of wood in an area with an extremely low RH, it would start to dry out, lowering its moisture content. In some cases, the drying wood could split or crack as the fibers lose moisture.

On the other hand, if you left a piece of wood in an area with an extremely high RH, it would start to absorb extra moisture from the air. In the short term, this could cause the wood to swell as it takes on more moisture.

However, these aren’t the only effects of high RH on wood quality.

Other potential effects of high RH may include, but not be limited to:

- Interference with Adhesives and Finishes. As the moisture content of wood rises, it can interfere with the setting of some adhesives, paints, and finishes. You may notice bubbles in paint or discoloration. When stress is applied to a glued joint, it may fail.

- Cupping. In wood flooring or other tightly-bound wood products where multiple pieces of wood are in edge-to-edge contact, the swelling of multiple wood work pieces can cause the wood to warp or cup as the edges push against one another.

The end result is an imperfect piece of woodworking that may need to be reshaped or even scrapped entirely.

However, if you know the relative humidity of a given area (and the %MC of the wood), you can avoid these problems.

How Can You Check RH for an Area?

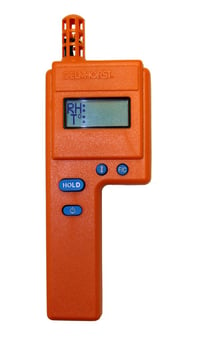

The easiest way to establish the relative humidity for a given area is to use a specialized tool—such as a thermo-hygrometer. These hygrometers check the ambient temperature and moisture saturation to establish a measurement of the RH of the air within a set +/- tolerance of the true RH value. This +/- of the measurement from the actual relative humidity of the air is called “sensor tolerance.”

The easiest way to establish the relative humidity for a given area is to use a specialized tool—such as a thermo-hygrometer. These hygrometers check the ambient temperature and moisture saturation to establish a measurement of the RH of the air within a set +/- tolerance of the true RH value. This +/- of the measurement from the actual relative humidity of the air is called “sensor tolerance.”

These devices vary somewhat in design, accuracy, and function from one to the next. A highly accurate thermo-hygrometer might have a sensor tolerance of +/- 2%, while a less accurate device might have a sensor tolerance of +/-4%.

What’s important is that these devices can give you a measurement of the RH of a given area—which gives you an idea of how your wood products might react when exposed to those conditions.

Many woodworking professionals use RH measurements to adjust their climate control settings in their production/acclimation areas to ensure that their wood products are perfectly acclimated.

For example, if RH is too high in the work area, then a woodworker might turn on the heater. Or, if the RH is too low, they woodworker might turn on the air conditioning. This can help to maximize the quality of the end product.

Of course, it takes an accurate hygrometer to reliably establish the RH of a given area—such as the HT-3000.

The next time you’re working with wooden products, do more than just check the %MC of the wood itself, be sure to check the relative humidity of the area where you’re storing your products.

Subscribe to Our Blog

Post Related

Determining Distribution of Moisture in Board Lumber