5 Factors for High-Quality Hardwood Flooring Installations

Hardwood flooring adds a beautiful and elegant touch to almost any building—whether it’s a home or a business. However, to achieve the most aesthetically-pleasing results, contractors need to take into account several different factors—including some things that may not occur to a layman.

What are these factors for high-quality hardwood flooring installations, and how do wood moisture meters figure into the equation for flooring work?

Here is a list of some key factors that contribute to the overall quality of wood flooring, and how moisture meters can help.

1: The Relative Humidity of the Installation Site

Relative humidity (RH) is a measure of how much moisture is in the air versus how much moisture would be needed for the air to be saturated at the current temperature. Warm, dry air would have a low RH value, while cold, damp air would have a high RH value.

How does relative humidity at the installation site affect hardwood flooring quality?

It’s because wood is a hygroscopic material—meaning that it will absorb and release moisture until it reaches equilibrium with its surrounding environment. As moisture is absorbed and released, wood flooring can warp slightly (or severely), creating gaps, warped surfaces, and other issues that ruin its aesthetic quality.

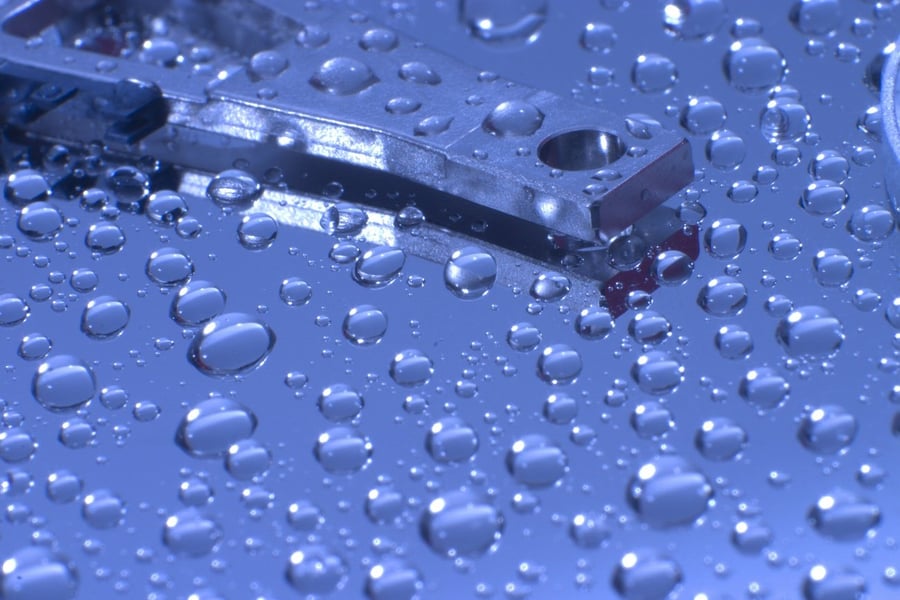

This is why it’s important to test the RH conditions at the installation site with a thermo-hygrometer prior to installing new hardwood flooring. With this information, you can use a wood moisture meter to gauge whether the wood is close to its equilibrium moisture content (EMC).

2: Moisture Content of Subfloor Materials

A wood flooring system is highly susceptible to moisture intrusion from subfloor materials. Moisture-compromised subfloors can release excessive amounts of moisture into hardwood flooring, causing warping, cupping, and buckling of the wood.

Because of this, it’s important to test subfloor materials with a moisture meter prior to installing hardwood flooring on top of them. In the case of concrete subfloors, a thermo-hygrometer with in-situ probes may be necessary to perform ASTM F-2170-compliant testing.

3: Moisture Content of the Hardwood Flooring

As the relative humidity conditions of the installation site and the excess moisture of subfloor materials can impact the quality of a hardwood flooring installation, the moisture content (%MC) of the wood at the time of installation can also impact its quality.

If the wood is too dry or too wet, it may gain or lose moisture after being installed until it reaches EMC. So, testing the moisture content of the wood before installing it is crucial for verifying that the wood is ready to be installed.

Also, if the wood flooring is excessively wet, it could pose a mold risk or become weakened. Once again, checking the moisture content with a wood moisture meter can help to identify moisture-compromised flooring wood.

4: Climate Control Systems in the Building

Many structures have climate control systems that are intended to help maintain a consistent temperature year-round. Some flooring installers make the mistake of shutting these systems off during the installation process. After all, nobody’s there except for workers, so why keep the A/C on?

The primary reason is that a climate control system helps to regulate the temperature and humidity conditions inside the building. By installing hardwood floors with the climate control shut off, a contractor is failing to account for how the relative humidity in the structure will affect the wood when the building is in use.

So, when planning an installation of new hardwood floors, it is important to turn on the climate control for the installation site and make sure that it is set to whatever settings would be typical for the building during the majority of the year. This helps to avoid changes in the wood’s EMC value later on.

On a related note, it’s also important to make certain that any doors, windows, or other openings that could allow outdoor air and moisture into the building are sealed off, as this can alter the relative humidity conditions at the installation site.

5: Wood Species Corrections for Moisture Tests

When testing the moisture of flooring with a wood moisture meter, it’s important to make sure that the meter is set for the right kind of wood (or to make wood species corrections to the readings manually). Otherwise, the moisture measurements taken may not be accurate, causing misjudgments in the installation process.

For example, Delmhorst’s wood moisture meters are calibrated for Douglas Fir wood. If you were to check African (Khaya) Mahogany flooring with one, a reading of 10% MC would indicate that the wood is actually at 12% MC. The difference between indicated reading and actual moisture content could mean installing flooring before it’s ready, compromising its quality later on.

Need help with using moisture meters to improve the quality of your hardwood floors? Contact the experts at Delmhorst today, or check out our flooring resource at the link below:

Subscribe to Our Blog

Post Related

How Accurate Are Moisture Meter Readings, Really?