4 Tips to Ensure the Best Moisture Content Measurements

When checking moisture content (%MC) in any material, whether it is wood, drywall, hay, grain, soil, paper, tobacco, or anything else, it’s important to ensure that you’re getting the most accurate moisture content value possible.

What is Moisture Content?

A good moisture content definition would be the amount of water in an object compared to its overall mass. Moisture content often affects the overall quality and safety of various materials and products—as such, it often needs to be strictly controlled. In many applications, a difference of just a few percentage points can have a significant impact on your decisions.

For example, when running a moisture content test on lumber, if the indicated %MC is 14% when the actual %MC is 20%, it may lead to wet, at-risk lumber being okayed as sufficiently dry. This could cause problems later on—such as mold growth or cupping. In hay, such a large difference in a bale of hay could lead it to catching fire.

So, it’s important to get as accurate and reliable moisture content measurement as possible. How can you ensure the best moisture content testing possible? Here are a few tips:

1: Use a Moisture Meter That’s Calibrated to the Material Being Tested

If you want to get accurate, quantitative measurements of moisture content, it’s important to use a moisture testing device that is specifically calibrated for that material. The truth is that there is no such thing as a truly universal moisture meter—moisture meter accuracy relies on the physical characteristics of the material being tested. So, each moisture meter has to be calibrated for a specific type of material.

The type of material a moisture meter is calibrated to provide accurate readings for is typically referred to as its “reading scale.” For example, a moisture meter calibrated to test moisture in hay is said to have a hay scale, whereas a wood moisture meter would have a wood scale.

If you were to use a wood scale meter on a piece of drywall, the moisture content measurement you would get would be off. So, it’s important to match the moisture meter reading scale to the material being tested if you want the most accurate measurements.

It should be noted that some moisture meters have multiple reading scales, such as having both wood and drywall scales.

2: Keep Species Corrections in Mind

Even when testing a specific type of material such as wood or grain, there may be some differences between different species. For example, Delmhorst wood moisture meters are specifically calibrated for Douglas Fir, which is the USDA standard. If used to test African Mahogany, the indicated moisture content would be lower than the actual moisture content.

To account for this, it’s important to use a species correction chart or a moisture meter that has a built-in species correction feature. Built-in species corrections make the process automatic, which is faster and easier than using a correction chart is. When using a meter with these built-in moisture content corrections, you simply have to program the meter to use the appropriate species correction before taking a reading.

3: Keep the Moisture Meter in Good Condition

Taking care of your tools is common sense for almost any application. When working with moisture meters, it can be critical for determining the accuracy of a moisture content test. However, the care process for moisture meters can vary depending on the type of moisture meter being used.

Some good general moisture meter care tips include:

- Regularly Cleaning the Testing Medium. The condition of the medium used to conduct a test has a significant impact on moisture meter accuracy. Regular cleaning is necessary to help prevent corrosion of the testing medium. If the testing medium is too corroded, it may be necessary to replace it. With pin-type moisture meters, the pins are usually fairly easy to replace if they’re broken or corroded. Pinless meters may need to have their scanning plates replaced if they are allowed to rust.

- Never Running the Moisture Meter On Undercharged Batteries. Low batteries may not output a consistent flow of electricity to the moisture meter—eventually causing damage and making the meter less accurate. Regularly checking batteries between uses and promptly swapping them out once their charge is too low can be key for maximizing the useful life and accuracy of any moisture meter.

- Storing the Moisture Meter in a Case Between Uses. Protecting your moisture meter from the elements is crucial for ensuring that it will last as long as possible. Keeping your moisture meter in a protective case will protect it from prolonged exposure to the elements as well as accidental drops and impacts that may occur while you’re in transit from one job to the next. This helps to keep the meter in good condition, preserving it for when you need it.

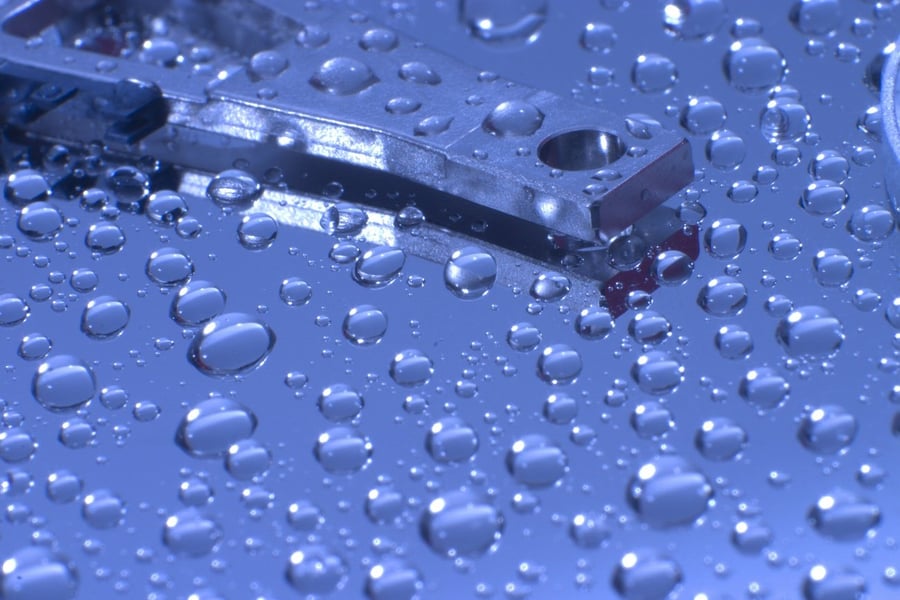

As a general rule, you should always avoid exposing a moisture meter to sudden impacts, submersion in water, and extreme temperatures. Any tool, no matter how rugged, will be adversely affected by such abuse.

4: Consider the Type of Moisture Meter You’re Using

Moisture meters fall into two broad categories based on the testing medium they use: Pin moisture meters and pinless moisture meters. These two moisture meter types have their own specific advantages and disadvantages over one another. To summarize a few of these advantages:

- Pinless meters are good at scanning large areas quickly and are a “non-destructive” test.

- Pin moisture meters are better at determining distribution of moisture throughout a material and can test moisture in uneven surfaces where pinless meters cannot be used.

Knowing when to use one versus the other is important for getting the best moisture content measurements in the least amount of time. In fact, many professionals carry both pin and pinless moisture meters (or 2-in-1 devices that combine testing methods) to improve their versatility and thoroughness.

For example, in restoration work, experts often use pinless moisture meters to quickly scan large sections of flooring, walls, and ceilings to minimize time spent on the task. Then, they use a pin meter to check whatever materials couldn’t be tested using the pinless meter—or to get the exact boundaries of a moisture-compromised area.

Need help choosing the right moisture meter to get the best moisture content measurements? Contact the experts at Delmhorst to learn more about moisture meters, or download the guide at the link below:

Subscribe to Our Blog

Post Related

The Best Moisture Meter for Commercial Use