What Moisture Content is Safe for Your Building Materials

One of the most frequently asked questions the Delmhorst team fields about moisture content (%MC) and moisture measurement is: “What’s a safe moisture content for X?” where “X” is whatever type of building material the person is preparing to test.

The answer to this question depends on a few things, such as:

- The type of building material in question.

- Ambient temperature and humidity conditions.

- Whether the building material will be exposed to the elements.

To help answer this question, here’s a list of some common building materials and safe moisture levels for each—plus a few tips for measuring moisture in each.

Safe Moisture Content Levels for Wood

Wood is one of the more challenging materials to nail down the “safe” MC for. Why? Because, wood is a hygroscopic material—it will readily absorb and release moisture until it reaches an equilibrium with its environment. In most cases, instead of defining a “safe” moisture level for wood, it is more useful to determine what the equilibrium moisture content (EMC) of wood is for a given installation site.

There are two primary methods by which people working with wood can determine whether it is in equilibrium with its surroundings:

- Taking Repeated Measurements over the Course of Several Days. This method has the person checking the wood use a wood moisture meter numerous times over the course of a few days. These moisture measurements should be repeated every few hours until the indicated %MC of the wood stops changing. Once the wood’s moisture content stops changing, it can be said to be at its EMC for that environment. This method is easy to use but time-consuming.

- Using Ambient Moisture Conditions to Determine EMC. The other way to determine what the EMC of wood should be is to check the relative humidity (RH) conditions of the area. The higher the RH is for a given area, the higher the EMC of the wood will be. For example, if the RH for the area is 40-45%, the EMC of wood should be about 8% MC. If the RH is between 58-63%, then the EMC of the wood should be about 11% MC. This testing method requires specialized relative humidity testing equipment, such as a thermo-hygrometer.

When checking the moisture content of wood, it’s important to use a moisture meter that is specifically calibrated for wood. Furthermore, it’s important to apply a wood species correction to the moisture measurement.

The reason for this is that different species of wood have different physical characteristics. This can impact the accuracy of a wood moisture measurement. For example, if a moisture meter is calibrated for Douglas Fir wood, but is used to check Longleaf Pine wood, the indicated moisture might be a point or two lower than the actual %MC of the wood.

Some moisture testing tools have a built-in species correction feature that allows users to get the correct readings with the push of a button. Others leave it up to the user to check their moisture measurements against a species correction chart and make the adjustments manually.

Safe Moisture Content Levels for Drywall

Drywall is a notoriously moisture-sensitive material, known to fall apart with ease when exposed to the slightest amount of moisture. In fact, gypsum, the material that drywall is made of, is so sensitive to moisture that drywall can be considered moisture-compromised if its %MC ever rises above 1%.

Drywall moisture content is usually measured using a pin-type moisture meter—partially because most drywall boards are too thin to use pinless moisture meters. There are pin moisture meters on the market that have specific drywall (aka gypsum) scale modes. With a gypsum scale meter, users can simply stick the meter in the drywall and activate it. Then, the meter will provide an accurate measurement of the moisture level in the drywall. If the reading is more than 1%, the drywall is too wet.

For people who have a pin moisture meter without a drywall scale, the meter’s reference mode can be used instead. While not as precise as drywall scale moisture measurements, the extreme sensitivity of drywall means that any significant indication of moisture should mean the drywall is moisture-compromised.

However, before taking the first reading, it may be helpful to test a known dry spot to get a baseline moisture reading for comparison. This is important because not all reference scales are the same, and a reading of “50” that may look high may just be how the meter reads dry gypsum.

Safe Moisture Levels in Insulation

Insulation in a structure can be especially sensitive to moisture intrusion. This is partially because insulation is usually hidden behind walls and ceilings, where mold can easily grow unnoticed. Additionally, loose-packed insulation materials can easily retain moisture once it is introduced.

In many cases, the moisture content of insulation won’t be checked until there is some obvious outward sign of moisture compromise—such as musty odors or discoloration in walls and ceilings from water soaking through. Unfortunately, any significant amount of moisture in insulation is enough to compromise its performance and pose a risk of mold growth.

When checking moisture content in insulation, it’s helpful to use a moisture meter that has an extra-long probe (or an optional probe socket that can accommodate one). This is useful because moisture pockets may be hidden deep in the insulation, well beyond the reach of 5/16” pins.

For insulation in walls, using a probe to punch through the wall itself may be necessary, as this helps to positively identify how far up the wall the moisture-compromised insulation extends. This, in turn, helps moisture meter users identify the source of the leak.

There is no one “insulation” reading scale, primarily because insulation formulations can change from one manufacturer to the next. So, insulation moisture testing is usually done with a reference scale moisture meter. Here are a few tips for testing moisture levels in insulation:

- Wear Protective Clothing. Many forms of insulation, such as fiberglass, are skin irritants. So, when testing moisture in insulation, it’s important to wear appropriate protection, such as goggles and gloves. This helps to prevent accidental contact between the insulation and skin.

- Take Moisture Readings from Multiple Angles. It is easy to miss a moisture pocket deep in insulation. To ensure more thorough moisture testing, it’s important to take readings from multiple angles to get a thorough assessment of the insulation’s moisture content.

- Test Relative Humidity Conditions Near Insulation. When preparing to check the moisture content of insulation, be sure to check the relative humidity in areas adjacent to exposed insulation, such as in the attic. Using thermo-hygrometers to test RH can help identify rooms where there is excess moisture, as the RH in these areas will be higher than rooms without moisture-compromised building materials. This helps narrow your search area.

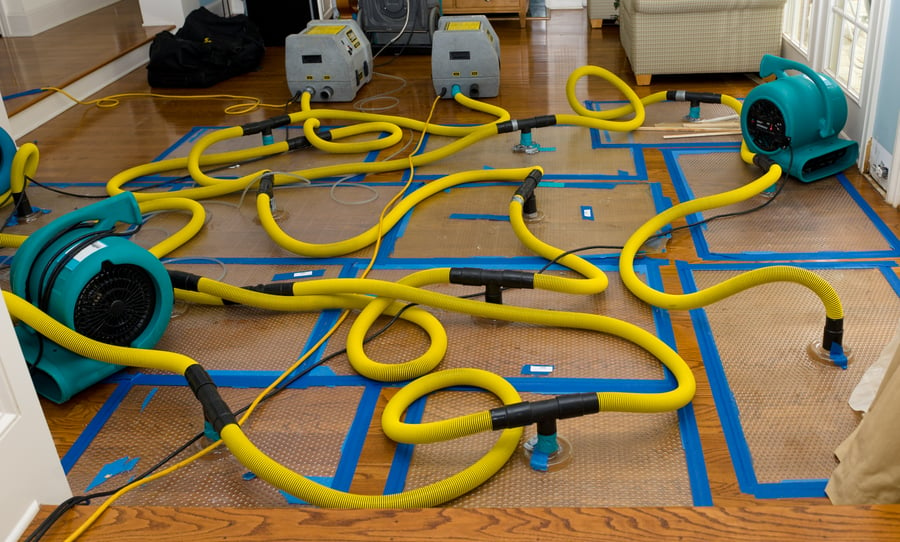

Choosing Moisture Testing Tools for Building Inspections or Restoration

Part of being able to accurately measure moisture content in building materials is having the right moisture testing tools for the job. For professionals looking to perform thorough moisture testing in buildings, this often means having a variety of moisture meters, electrodes, and humidity testing tools.

Some moisture testing tools that a professional might use for measuring moisture in buildings include:

- TechScan Pinless Meter. This pinless moisture meter uses an analog display to provide easy-to-read assessments of moisture content in wood and other building materials. Pinless meters like the TechScan excel at measuring moisture over a large area very quickly. The wood scale provides accurate, quantitative readings of moisture over the range of 5% to 30% MC in wood. Meanwhile, the reference scale can be used to provide qualitative moisture assessments in other building materials.

- BD-2100 Pin Meter. This pin-type moisture meter is one of Delmhorst’s most popular models. The BD-2100 has three different moisture testing scales: wood, drywall, and reference. The wood and drywall scales provide accurate moisture measurements in their respective materials. In the reference scale mode, the meter can provide qualitative moisture assessments in other building materials, such as fiberglass insulation. The universal probe socket at the top of the meter can accommodate any Delmhorst electrode. To ensure reliability, the BD-2100 has a built-in calibration check feature to quickly test meter accuracy.

- HT-4000 Thermo-Hygrometer. This relative humidity testing tool can monitor temperature, dew point, vapor pressure, and grains per pound (GPP) to provide users with a complete assessment of humidity conditions in a given area. The HT-4000 is often used to check for areas in a building with unusually high relative humidity, which can help narrow the search area for a leak.

- QuickNav 3-in-1. This moisture meter combines the functionality of pin and pinless moisture meters with a built-in thermo-hygrometer to create one robust moisture testing tool. The versatility of the QuickNav makes it ideal for a range of moisture testing tasks—and saves space on the tool belt by not making users carry three different devices. The pin mode supports both wood and drywall moisture reading scales, while the pinless mode uses a reference scale. This helps the QuickNav be useful for use in most building materials.

Which of these moisture testing tools is the best for your needs? The answer actually depends on what you’re looking for in a moisture meter. If you’re looking for a moisture testing tool for the most experienced professionals on your team to use for all of their moisture testing tasks, then an all-in-one device like the QuickNav might be your best bet. However, some users prefer a simpler moisture testing tool like the BD-2100, which is simple enough for a beginner to use but has enough advanced features to be useful to a seasoned pro.

It’s also important to consider what building materials you expect to test the most frequently. If you are constantly checking drywall and insulation, pin meters will probably be ideal for your needs. If you are going to be testing flooring and solid wood joists or similar materials, and need to cover large areas quickly, then a pinless moisture meter like the TechScan might be more ideal.

Need help choosing the right moisture testing tools for your needs? Contact the experts at Delmhorst today for more help and advice!

Subscribe to Our Blog

Post Related

How Moisture Meter Technology Benefits the Water Damage Restoration Industry