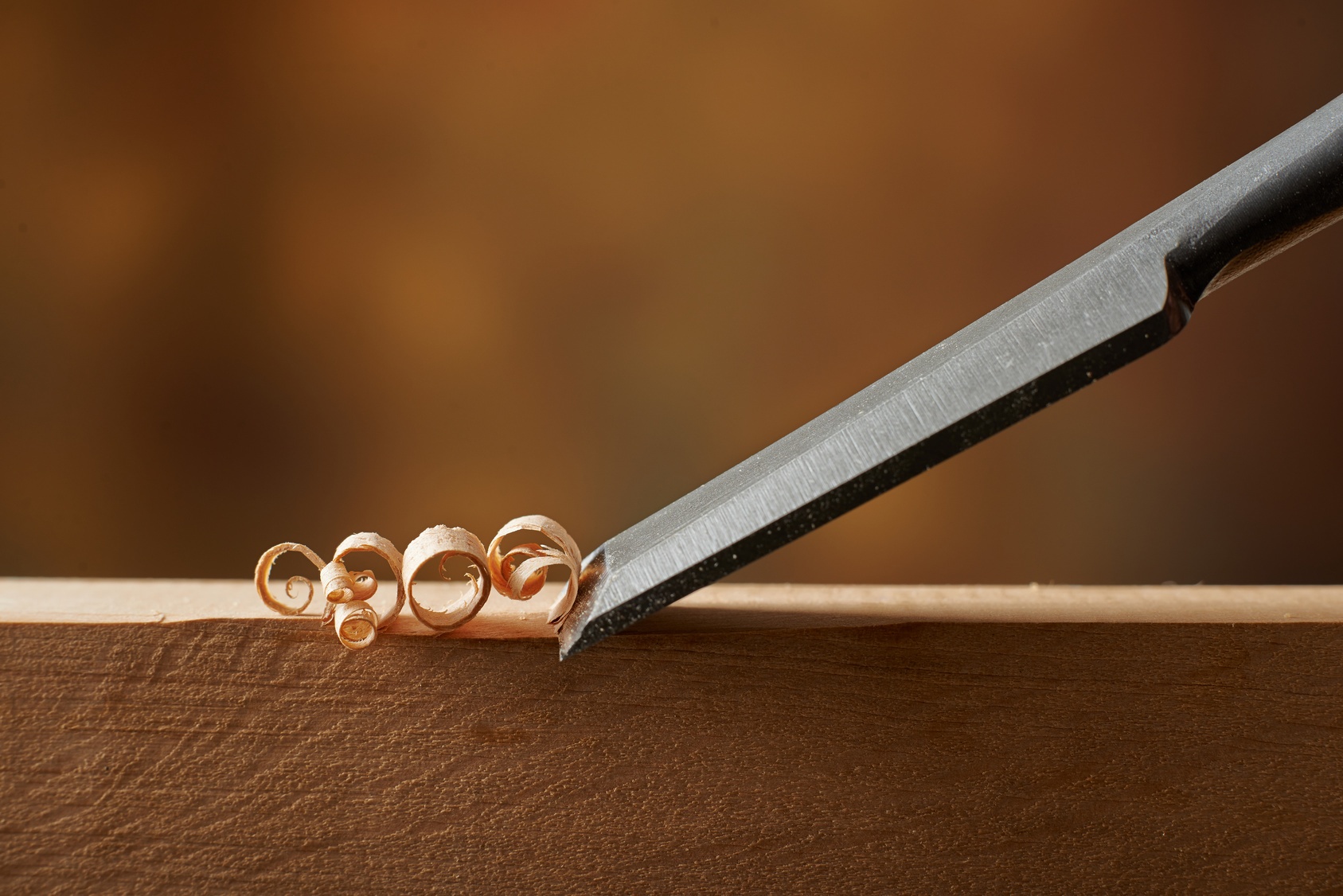

3 Reasons You Should Use a Moisture Detector for Woodworking

When creating any woodworking project, using a moisture detector that’s been specifically calibrated for wood is a must.

A few reasons why you should use a moisture detector for woodworking include:

1: Verifying That Wood is at its Equilibrium Moisture Content Prior to Working with it

Wood is a hygroscopic material—meaning that it will absorb or give off moisture until it reaches a balance with its environment. Once the wood has reached this balance, it is said to have reached its equilibrium moisture content (EMC). EMC is based on a combination of local humidity, temperature, and the specific characteristics of the wood itself, so it will vary from one case to the next.

Moisture detectors for woodworking are an integral part of making sure that wood has reached EMC by allowing you to track the precise moisture content percentage (%MC) of the wood. Simply check the %MC of the wood daily until it stops changing.

This process may take several days, depending on the environmental conditions, but the results are well worth the time taken. Just to be safe, some woodworkers give the wood an extra day to further acclimate after getting two or three identical measurements in a row.

Verifying that wood is at its EMC is vital because it prevents surprises such as swelling or cracking after you’ve assembled your woodworking project.

For example, if wood is below EMC when you use it, it could absorb moisture from the air and swell afterwards, ruining joints in furniture or causing tightly-bound pieces of wood in a wood product to warp and crack as they grind against one another.

By checking for EMC first, you can make sure the wood’s moisture content won’t change after assembly. This can save a lot of time, money, and effort by preventing potential issues caused by fluctuating moisture content in wood.

2: Identifying When Wood is Too Wet to Use

Aside from verifying whether or not wood has reached EMC, moisture detectors for woodworking can help identify pieces of wood that are simply too wet to use for your woodworking project.

Damp, moisture-packed wood can not only develop mold, but the moisture that such wood leaks could cause paint and finish failure, and compromise glue joints. This can ruin the appearance of a finished product and even compromise joint integrity for furniture projects.

With a wood moisture detector, you can get a clear, quantifiable %MC measurement of the wood you’re working with. This way, you know for certain whether or not the wood is too wet to use.

3: Improving Overall Quality for Your Woodworking

Because of their ability to verify that wood has reached EMC and to identify whether wood is too wet for use, woodworking moisture detectors are an invaluable tool for improving the overall quality of your woodworking projects.

By verifying EMC and spotting wet wood that’s not ready for use, you can avoid many common problems that bring down the quality of your woodworking projects.

In short, moisture detectors for woodworking can help you make better-quality products that you can be proud of.

Need help finding a moisture detector for your woodworking needs? Check out our list of woodworking moisture meters today!

Subscribe to Our Blog

Post Related

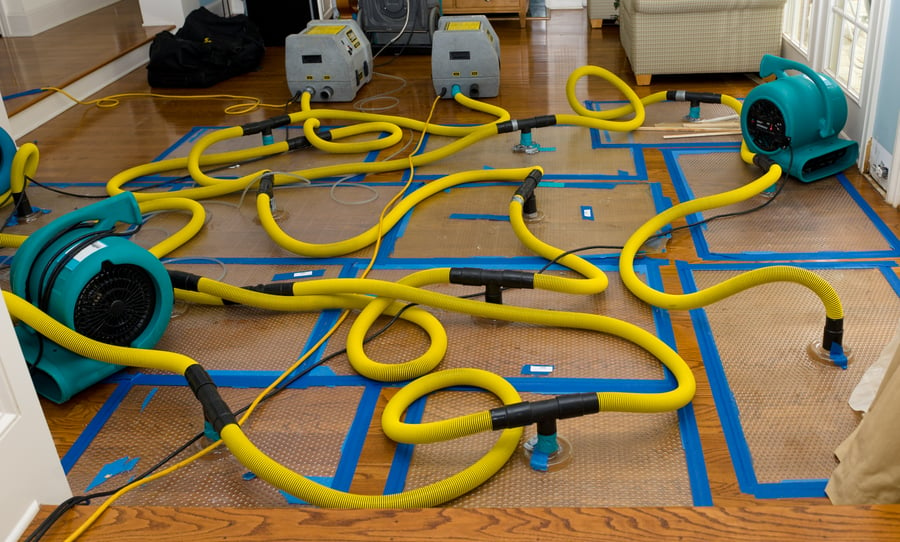

How Moisture Meter Technology Benefits the Water Damage Restoration Industry