Flooring System Solutions: How to Better Test Moisture Content

Testing moisture content is a critical part of nearly any flooring system installation process. Whether you’re preparing to install wood, tile, or other flooring types, moisture can have a significant impact on the flooring system.

For example, if there is an excessive amount of moisture in a subfloor, then that moisture can be absorbed by the adhesives used to bond tile and other flooring—compromising the integrity of the bond. Wood floors are especially susceptible to moisture-related issues and may cup, crack, or warp if the wood has too much or too little moisture when they are first installed.

The question isn’t “should you test moisture content in your flooring systems?” but rather “what’s the best way to test moisture content in your flooring systems?

Here are a few flooring system solutions for testing moisture more quickly and thoroughly:

Solution #1: Test Relative Humidity Conditions at the Installation Site First

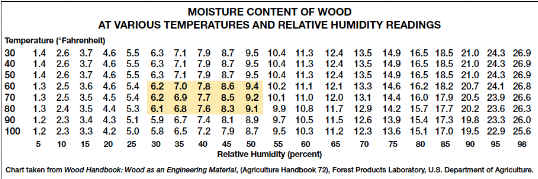

When installing wood flooring systems, the relative humidity (RH) of the installation site can greatly affect the wood. Because wood is a hygroscopic material, it will absorb or let off moisture until it reaches an equilibrium with the surrounding environment. Normally, testing if wood has reached its equilibrium moisture content (EMC) can take days as you test and re-test the wood to see if its moisture content (%MC) has stopped changing.

However, there’s a faster way to check if the flooring wood is at EMC for the installation site—if you know what the RH and temperature conditions of the installation site are. This can easily be done using a thermo-hygrometer.

Simply set up the thermo-hygrometer in the area where the flooring system will be installed, make sure that any climate control systems are on and set to their normal use settings for at least 72 hours (which you would have to do prior to a normal EMC test anyway), and activate the hygrometer.

Check the RH measurement provided by the hygrometer and the room’s current temperature, and compare it on the chart below:

After recording your results, simply take a moisture reading of your wood flooring to see if the wood’s moisture content is close to the EMC value given in the chart.

This method is much faster than trying to test flooring wood multiple times over the course of several days. Even if the wood is not at its EMC value, you’ll at least know how close it is.

Solution #2: Using Pinless Moisture Meters on Stacks of Flooring Wood

Pinless moisture meters can be a great tool for testing moisture in flooring systems because they can measure moisture in your flooring wood without leaving pinholes in it.

When testing the moisture content of wood flooring prior to installation, one trick that some contractors use is to stack a bunch of flooring planks one on top of the next, and scan the stack from the side with a pinless meter to get an average of the %MC of all the planks the meter is in contact with.

This trick works best with flooring planks and strip flooring pieces that have flat sides—parquet flooring that is engineered to snap-fit together won’t provide a smooth, flat contact surface from the side.

Solution #3: Using Drywall Meters for Gyp-Crete Flooring Systems

Gyp-Crete is a mixture of sand and gypsum that is often used in commercial buildings because of its excellent fire resistance and soundproofing qualities. However, the inherent sensitivity of gypsum to moisture exposure makes monitoring moisture in Gyp-Crete extremely important.

Thankfully, because Gyp-Crete is primarily (up to 95%) gypsum, drywall moisture meters are highly compatible with this flooring material. As you wait for the Gyp-Crete underlayment finish curing, you can use a drywall moisture meter to check the material and test if it’s ready to be built over yet.

After the Gyp-Crete hardens, simply push the pins of the drywall moisture meter to the desired depth and take a moisture measurement. Because of gypsum’s extreme sensitivity to moisture, the reading should be below 1% MC to indicate that the Gyp-Crete underlayment is ready.

This can help you minimize the time you wait for the underlayment to cure by letting you know at once when it is ready—rather than having to wait an extra day or three to make sure.

Want to learn more about testing moisture in flooring systems? Check out our free guide to measuring moisture in flooring, or contact us today! If you have a favorite trick for testing moisture in flooring systems, share it in the comments section below!

Subscribe to Our Blog

Post Related

What to Avoid When Testing Moisture in Your Flooring System