3 Reasons to Use a Pinless Moisture Meter

When shopping for a moisture meter, users have two types of meters to choose from: pin meters and pinless moisture meters.

When shopping for a moisture meter, users have two types of meters to choose from: pin meters and pinless moisture meters.

Pin-type meters use two electrodes that are inserted into the surface of the material being tested. An electric current runs between the two points of contact—effectively creating a circuit. The resistance to the current is measured and used to determine how much moisture is present—the more moisture there is, the less resistance there will be.

Pinless meters use electromagnetic frequencies to measure moisture in different materials. As the meter “scans” the material, it monitors the fluctuations in the electromagnetic wave to determine the moisture content present in the material.

Both of these meter types have distinct advantages and disadvantages for their use. Here are a few of the reasons why professionals in different industries might want to use a pinless meter over a pin-type meter:

1: To Avoid Damaging Materials

Any professional who works with materials where preserving their appearance is a must will typically prefer pinless moisture testing methods to pin-based ones.

Pin holes from pin-type meters can affect the aesthetic value of wood flooring and decorative materials—which can add extra work after a job to cover up or plug pinholes and make the repairs blend smoothly.

Pinless meters don’t have to puncture the delicate surface of wood flooring, tables, boards, and other materials to get a reading of their moisture content (%MC). This is why pinless meters are sometimes referred to as “non-destructive” moisture meters.

2: To Conduct Preliminary Tests of Concrete Surfaces

While pinless moisture meters cannot provide quantitative readings indicating precise %MC measurements in concrete—there are too many variables and the sample depth is too shallow in most poured concrete applications—they can provide qualitative, preliminary readings using the ASTM F2659 standard.

This can be a quick means of verifying if the concrete needs more testing under the standard, or to see if it is ready for the application of a sealant.

The process for testing concrete under ASTM F2659 is roughly as follows:

- Turn off all accelerated drying equipment at least 96 hours (4 days) before testing;

- Check for standing water on the surface of the concrete;

- Remove all adhesive or other “deleterious residues” from the concrete’s surface;

- Place the scanning plate of the pinless meter flush with the concrete (flat contact produces better readings); and

- Take a reading in the reference scale mode.

The reference scale provides a general indication of moisture content. It may be necessary to consult the owner’s manual to see how to set the meter to reference mode, and to verify what constitutes a “high” or “low” reading for that meter’s reference scale – different meters have different value ranges for their reference meters.

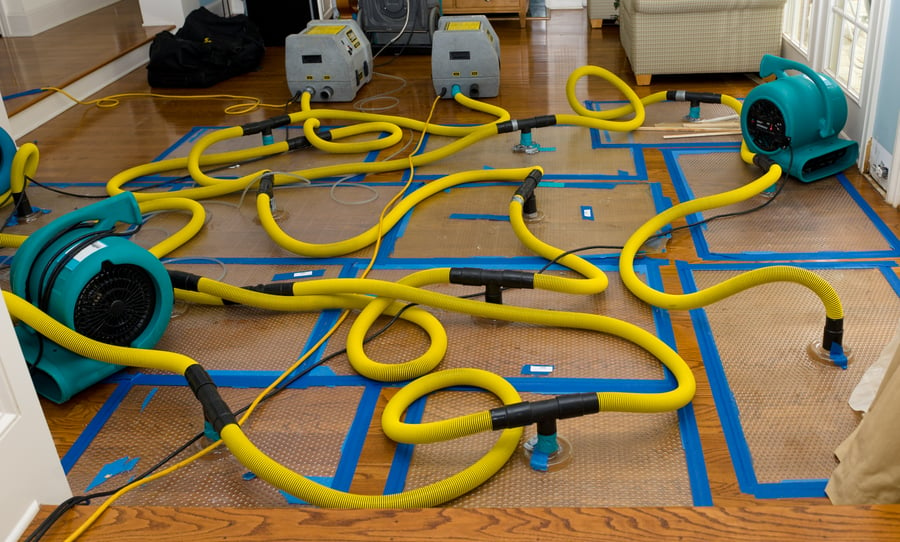

3: To Get Measurements Over a Large Area Quickly

One of the primary advantages of using pinless moisture meters is that they cover a larger area than pinless meters with each test, and can be removed and planted in a new spot quicker. This lets pinless meter users thoroughly test larger sections of different materials much faster than they could with a pin-type meter.

For professionals, this extra speed can save a lot of time (and labor expenses) on the job. For example, if a restoration expert using a pinless meter can thoroughly test for moisture in a 1,000 sq. ft. room in 2 hours with a pin-type meter, and 1 hour with a pinless meter, a 16,000 sq. ft. building could be thoroughly tested in 2 working days’ worth of labor (16 hours) rather than 4 (32 hours). At $15/hour, that’s $240 of labor saved on one job. In less than a month, most pinless moisture meters would pay for themselves in labor savings alone.

Overall, pinless moisture meters are incredibly useful tools for many professionals in different industries. However, there are some situations for which a pin-type meter is better suited. When should you use which meter? Get the answer by checking out Delmhorst’s 101 guide to learn more about both types of moisture meter!

Subscribe to Our Blog

Post Related

When Are Moisture Meters Useful for Concrete Testing?